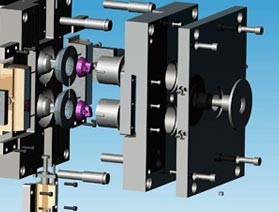

Product and Mold Design

Product Development and Plastic Injection Mold Design

API provides top notch engineering services by combining proven design standards with the most modern techniques available today for designing and manufacturing plastic injection molded parts.

- Engineers and designers partner with our customers to bring concept to reality using the most modern techniques in our computer design center.

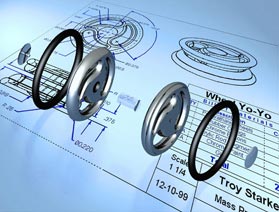

- 2-D prints and 3-D AutoCAD designs

- Mastercam 7 Machine Series

- Mold flow Analysis – Moldex 3D

- Autronic Plastics engineers offer plastic design assistance and become a valuable extension of your product development team. API helps to design your product with tool building, material selection, and part manufacture in mind to help control cost and prevent problems before they arise.

Research & Development

API is an engineering and manufacturing company that was founded to research, engineer, and manufacture plastic injection molded parts

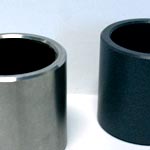

- API works very closely with multiple resin suppliers and rigorously tests a multitude of materials to support your ever-changing needs and challenges through innovation and creativity

- Our engineers work directly with all parties that could add value to the design process

- Our engineering and quality assurance teams meet with engineers, quality assurance, sourcing, production, management, and sales teams to ensure products are delivered as expected, while minimizing development time and cost

- Autronic's 60 years of expertise in developing our "Right the First Time" process set us apart from the competition

- API can use liquid or powder color for that perfect color match

- Custom built or off-the-shelf robotics can help reduce expensive assembly costs

- Two shot or insert molding allows helps reduce cost and lead times for high volume production

- API can reverse engineer and duplicate an existing part and can even make modifications or improvements for both the manufacturing process and design

Right the First Time Design & Plastic Prototyping

API strives to achieve a "Right the First Time Design" without over-design or under-design to reduce costs, improve speed to market, and avoid costly aftermarket solutions.

- Our in-house, rapid prototyping FDM Machine (Fused Deposition Modeling with soluble support removal) allows our customers to have a physical plastic product sample before a mold is built

- API's engineers analyze prototypes for manufacturing feasibility, functionality, and performance to resolve manufacturing issues before they arise