Custom Plastic Injection Molding

Autronic Plastics, Inc. is a custom plastic injection molding company in Long Island, NY dedicated to providing quality services. API's in-house designers and engineers bring customer products from concept to completion.

- Specializing in difficult-to-process engineering resins, metal replacement, and precision plastic components

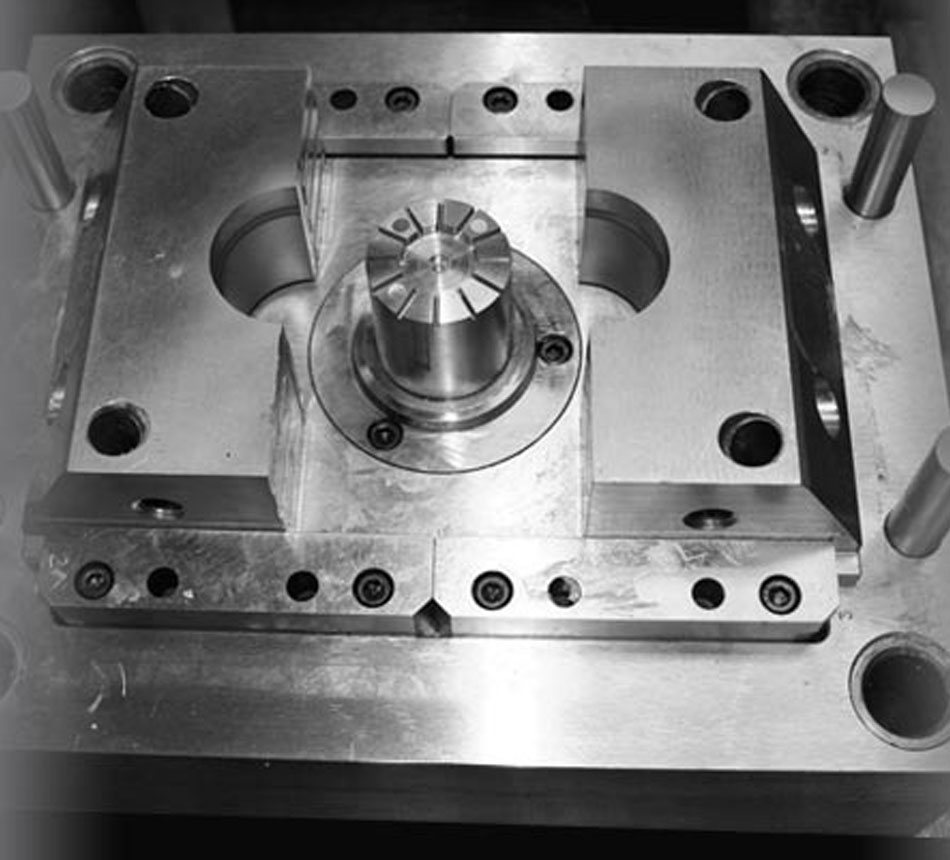

- Full service mold shop with an on-site tool room, automation lab and rapid prototyping

- Expert mold designers – multi-action, hot-runner, 3-plate, 2 shot, over-mold, and insert molds