Value Added Services

Engineering Resins

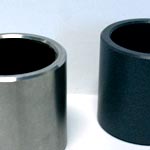

API's versatility is displayed by the vast array of resins that are used in manufacturing plastic components.

- Autronic Plastics excels in working with difficult-to-process engineering resins including PEEK, Ryton, Lexan, Valox, and Polyarylsulfone

- API has 60 years of experience in manufacturing plastic components using high temperature and high performance plastic injection molding resins (PC, ABS, Acrylic, PVC, TPE, PI, PEI, PPS, PES)

- Glass filled, composites, or nanoclay materials and added reinforcements, such as plasticizers, pigments, or modifiers, can help to add strength, durability, and increase product performance

- Experienced in molding thermoplastic elastomers (TPEs) and thermoplastic polyurethanes (TPUs) for rubber replacement applications to improve strength, processablility & colorability, cut & abrasion resistance, and load bearing capacity while simultaneously reducing cost

- Autronic Plastic's chemical bonding capabilities (polyamide to polyethylene) and ability to fill resins comprised of up to 94% metal loaded alloys make us the molder of choice for many industries

- Current markets: Security, Lighting, Military, Defense, Medical/Dental, Life Safety, Aerospace, Healthcare, Automotive, Fasteners, Displays, and more

Selecting the proper material for a specific application can be challenging and overwhelming. API has 60 years of knowledge and experience processing a vast array of resins and can assist in material selection. Check out API's basic plastic resin guide to help decide which thermoplastic is best for your part.

High Transparency

API has been an expert in molding exit signs and lenses for Clear-Vu Lighting for over 20 years.

- High performance, low cost resins

- Unique molding experience for flawless finishes

- Color matches to perfection

Concurrent Engineering and Development

The API designers and engineers draw upon over 250 years of combined experience to provide valuable insight and expertise throughout the entire development process.

- Non-disclosure practices assured

- Joint product development and consulting with customer

- Full service prototyping capabilities and lowest cost to market objectivity

- Value engineering and analysis workshops at customer facility when needed

Automated Assembly and Secondary Production

API's on-site automation lab performs a multitude of secondary operations to help reduce cost and shorten lead times.

- API automation helps to reduce overall part cost by reducing cycle times and manual labor

- Automation helps to increase consistency and level of quality by reducing waste and variation

- Shortened cycle times allow you to bring your product to market faster!

Autronic Plastics can support various levels of automation depending on the needs and budget you are looking to achieve:

- Resin material and handling

- Part, runner, or sprue picking and separating

- Overmold or insert molding automation

- Part placement, positioning, sorting, or stacking

- In-line or cellular robotics

Distribution and Logistics

Whether you need a global rollout or customized parcel shipments, Autronic Plastics, Inc. is your flexible supply network partner.

- One-day access to anywhere in the continental US

- Global exportation expertise from multiple distribution points

- Adaptive Supply Network and Integrated Supply Chain Management

- Integrated SAP / MRP / ERP systems / Business Objects

- Advanced project management and Sharepoint tracking system

- Dedicated customer service team that provides personal attention to your account

- Optimized production and inventory lot sizes with minimized work in progress (WIP)

- Global manufacturing and delivery options

- Custom shipments for complex parcel level

- Direct to client rollout

- Full truck load (FTL) or less than load (LTL) shipments

API's experienced, cross-functional teams manage the entire process of bringing your plastic products from concept to market.