Plastic Manufacturing: Plastic Injection Molding

Autronic Plastics, Inc. has nineteen in-house plastic injection molding machines, 24/5 manufacturing on the molding floor, and additional capacity when running multiple weekend shifts to bring your product to the market quickly and efficiently.

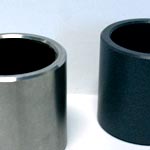

API's core manufacturing competencies include thermoplastic molding, insert molding, two-shot molding, transfer tooling, and assembly.

- Insert molding is often used to reduce the costs associated with adding inserts as a secondary operation. API works with customers to source a high quality insert and offers both manual and automated insert molding options depending on customer requirements for timing and cost.

- Two-shot molding is another way API can reduce costs associated with multiple handling. API can shoot two different resins in the same process to add additional features such as grip, color variation, added protection, sealing, and even chemical bonding.

Combining our various molding methods with fully automated, semi-automated, or manual assembly allows API to be a turn-key plastic manufacturer and a one-stop shop.

- Plastic Injection Molding Equipment

- 45 Ton, Toshiba (1)

- 60 Ton, Toshiba (1)

- 90 Ton, Toshiba (1)

- 110 Ton, Toshiba (1)

- 190 Ton Toshiba (1)

- 240 Ton, Toshiba (3)

- 250 Ton, Toshiba (4)

- 310 Ton, Husky (1)

- 310 Ton, Toshiba (1)

- 390 Ton, Toshiba (3)

- 550 Ton, Husky (2)

Plastic Injection Mold Tooling Transfer Made Easy

Autronic Plastics engineers work with you to identify issues early in the mold transfer process, including mold quality and compatibility concerns, and will make recommendations for resolution.

API can assist in the facilitation of moving your plastic injection mold, qualify the mold for future production, and make mold repairs in our full service tool room if necessary.

API is committed to adding value to your product through improved quality and productivity and will work to ensure there is no gaps in supply.

Autronic Plastics molding accessories improve quality and efficiency

API combines many different accessory options to the wide array of plastic injection molding capabilities to improve cycle times, reduce lead times, and deliver high quality plastic products at the best price possible.

- Accessory Equipment

- Quick-change hopper connections

- Liquid color mixing systems and liquid color feeders

- Mold master 60 zone manifold controller

- Full servo high Speed assembly robots / Netliner robots for Husky plastic injection mold machines

- Gima 877 Sealers and Assembly Machine

- Rotary assembly work centers with integrated ultrasonic welders

- AEC Whitlock Vactrac Series automatic PLC-controlled material conveying system including PLC 18-station controller

- AEC-Nelmor SE-50 particle-fine separator and 5B-40 Dryer

- Grinders including AEC-Nelmor 15 hp (460 volt) and Polymer Systems 10 hp grinder

- Hopper Loaders, Desiccant Dryers, and HPD-7 portable drying system (300 lb capacity)

- AMI 24 Zone hot-runner controls

- Advantage mold thermolators and Husky mold temperature controller

- Novatek Central Material Handling System Receivers

- 5.5 ton Konecrance overhead crane w/full hoists and controls

- Marley Aquatower 4862 60 ton cooling tower

- 750 gallon process and tower water pump tank

- 10 ton (CTI) portable chiller

- Lantech Q-300xt pallet wrapper

- Forklifts/Pallet Trucks (Toyota 4500 lb, Crown 3500 lb reach, Crown 4000 lb pallet, Hyster 155 Forklift)

- Freightliner 26' Straight truck

Injection molding: Manufacturing 5-gallon plastic pail handles and plastic bucket grips