Basic Resin guide

Commodity resins are often inexpensive and easy to process plastics. They are used in all kinds of applications, including toys, packaging, and consumer products.

Engineering resins are plastic materials that have better mechanical and/or thermal properties than commodity plastics. These high strength plastics are often resistant to high temperatures, wear, and corrosives. Engineering plastics are often used in wood or metal replacement applications as a means of reducing cost or weight while maintaining strength and performance.

Commodity Resins-

ACRYLONITRILE BUTADIENE STYRENE (ABS)

Strength: Low – Med Strength at Elevated Temp: Low Resistance to Impact: High Material Flow: Fair – Good Resistance to Shrinkage/Warpage: Fair – Good Resistance to Flash: Good Cost of Resin: Low – Med Impact on Mold (wear): Low Impact Advantages: Chemical resistant, easily processed, good surface finish, RoHS Compliant, flame retardant Disadvantages: Limited weathering resistance Common Uses: Consumer Goods, auto interiors, toys Brand Examples: Cycolac, Lustran, Trilac -

ACRYLIC (PMMA)

Strength: Med Strength at Elevated Temp: Low Resistance to Impact: Low Material Flow: Good Resistance to Shrinkage/Warpage: Good Resistance to Flash: Good Cost of Resin: Med Impact on Mold (wear): Low Impact Advantages: Good weatherability, insulation, clear/colorable Disadvantages: Common Uses: Glass replacement, lenses, casings, aquariums Brand Examples: Acrylite, Kydex, Plexiglass -

HIGH DENSITY POLYETHYLENE (HDPE)

Strength: Low Strength at Elevated Temp: Low Resistance to Impact: High Material Flow: Excellent Resistance to Shrinkage/Warpage: Fair Resistance to Flash: Poor Cost of Resin: Low Impact on Mold (wear): Low Advantages: Food contact acceptable, easily processed Disadvantages: High thermal expansion, poor weather resistance Common Uses: Toys, Buckets Brand Examples: Chevron, Dow, Relene - POLYPROPYLENE (PP)

Strength: Low Strength at Elevated Temp: Low Resistance to Impact: High Material Flow: Excellent Resistance to Shrinkage/Warpage: Fair Resistance to Flash: Poor Cost of Resin: Low Impact on Mold (wear): Low Advantages: Food contact acceptable, easily processed Disadvantages: Degraded by UV Common Uses: Consumer Goods / Living Hinge Applications Brand Examples: Hival, Lupol, ProFax - POLYETHYLENE (PE)

Strength: Low Strength at Elevated Temp: Low Resistance to Impact: High Material Flow: Good Resistance to Shrinkage/Warpage: Excellent Resistance to Flash: Poor Cost of Resin: Low Impact on Mold (wear): Low Advantages: Corrosion resistant, low weight, high flexibility, food contact acceptable, easily processed Disadvantages: Poor weatherability, high thermal expansion Common Uses: Toys, Bearings, Buckets Brand Examples: Bapolene - POLYSTYRENE (PS)

Strength: Low – Med Strength at Elevated Temp: Low Resistance to Impact: Low – Med Material Flow: Good Resistance to Shrinkage/Warpage: Fair – Good Resistance to Flash: Fair Cost of Resin: Low Impact on Mold (wear): Low Advantages: Food contact acceptable, flame retardant, fast cycle time, expandable Disadvantages: Poor solvent and chemical resistance Common Uses: Toys, packaging, product casings (Crystal PS for clear cases, cups) Brand Examples: Starex, Styron - POLYVINYL CHLORIDE (PVC)

Strength: Low – Med Strength at Elevated Temp: Low – Med Resistance to Impact: Med Material Flow: Med Resistance to Shrinkage/Warpage: Med Resistance to Flash: Med Cost of Resin: Low Impact on Mold (wear): Med – High Advantages: Flame retardant, high Gloss, UV resistant Disadvantages: High density, UV sensitive Common Uses: Soft, flexible parts; fencing; containers, can also be rigid to add strength Brand Examples: Mixvil, Vital-line - STYRENE ACRYLONITRILE (SAN)

Strength: Med Strength at Elevated Temp: Low – Med Resistance to Impact: Low Material Flow: Med Resistance to Shrinkage/Warpage: Med Resistance to Flash: Med Cost of Resin: Med Impact on Mold (wear): Low – Med Advantages: Good weatherability, chemical resistant, high Clarity, good processability Disadvantages: Higher water absorption and yellowing than PS Common Uses: Electical and Automotive applications, cosmetic Packaging, containers Brand Examples: Absolan

-

ACRYLONITRILE BUTADIENE STYRENE (ABS)

- Engineering Resins

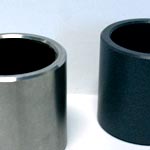

- ACETAL (POM)

Strength: Med Strength at Elevated Temp: Low – Med Resistance to Impact: Med Material Flow: Fair Resistance to Shrinkage/Warpage: Fair Resistance to Flash: Good Cost of Resin: Med Impact on Mold (wear): Med Advantages: Low fatigue, low moisture sensitivity, chemical resistant, good chemical properties Disadvantages: Poor resistance to acids, UV Degradation Common Uses: Springs, bearings, valve parts Brand Examples: Ashlene, Celcon, Delrin - POLYBUTYLENE TEREPHTHALATE (PBT)

Strength: Med Strength at Elevated Temp: Low Resistance to Impact: High Material Flow: Fair Resistance to Shrinkage/Warpage: Fair Resistance to Flash: Fair Cost of Resin: Med – High Impact on Mold (wear): Low – Med Advantages: Dispersible, good electrical properties, food contact acceptable Disadvantages: Difficult to fill thin parts, poor resistance to acid Common Uses: Electronic components, housings, automotive connectors Brand Examples: Celstran, Celanex, Valox - PBT / PET (GLASS FILLED)

Strength: High Strength at Elevated Temp: Med Resistance to Impact: Med Material Flow: Fair – Good Resistance to Shrinkage/Warpage: Poor – Fair Resistance to Flash: Fair Cost of Resin: Med – High Impact on Mold (wear): Med Advantages: Low moisture absorption, high stiffness-to-weight ratio, medical and UV resistant grades Disadvantages: Common Uses: Structural parts, housings, automotive components Brand Examples: Crastin, Rynite, Makroblend - POLYETHYLENE TEREPHTHALATE (PET)

Strength: Med Strength at Elevated Temp: Med Resistance to Impact: High Material Flow: Good Resistance to Shrinkage/Warpage: Med Resistance to Flash: Med Cost of Resin: Med Impact on Mold (wear): Low – Med Advantages: Chemical resistant, clarity, easily processed Disadvantages: Common Uses: Infant products, sterilizer lids, dishwasher parts Brand Examples: Celanex, Ramapet - POLYCARBONATE (PC)

Strength: Med Strength at Elevated Temp: Med – High Resistance to Impact: High Material Flow: Fair Resistance to Shrinkage/Warpage: Fair – Good Resistance to Flash: Good Cost of Resin: Med – High Impact on Mold (wear): Low Advantages: RoHS compliant, dimensionally stable, easily Processed Disadvantages: Fair chemical resistance, degrades during extended processing times Common Uses: Lenses, light covers, single use containers Brand Examples: Hopolex, Lexan, Makrolon - POLYETHER ETHER KETONE (PEEK)

Strength: High Strength at Elevated Temp: High Resistance to Impact: High Material Flow: Good Resistance to Shrinkage/Warpage: Med Resistance to Flash: Med Cost of Resin: Med – High Impact on Mold (wear): Med Advantages: Chemical resistant, abrasive resistant, corrosive and hydrolysis resistant, can be filled with carbon fiber, graphite, molybdenum disulfide, etc. for lubricating properties and enhanced mechanical strength, food contact acceptable, good sterilizability Disadvantages: Common Uses: Engineering applications, medical/healthcare Brand Examples: Victrex - POLYETHER IMIDE (PEI)

Strength: High Strength at Elevated Temp: Med Resistance to Impact: Med Material Flow: High Resistance to Shrinkage/Warpage: Med Resistance to Flash: Med Cost of Resin: Med – High Impact on Mold (wear): Med Advantages: Flame Retardant, good chemical resistance, good processability Disadvantages: Notch sensitive, limited colorability Common Uses: Medical/healthcare, automotive, aerospace, metal replacement, thin walled parts Brand Examples: Duron, Ultem - POLYETHERSULFONE (PES) / POLYSULFONE (PSU)

Strength: High Strength at Elevated Temp: Med – High Resistance to Impact: Med Material Flow: Low – Med Resistance to Shrinkage/Warpage: Med Resistance to Flash: Med Cost of Resin: High Impact on Mold (wear): Med Advantages: Acid resistant, thermal stability, hydrolysis resistant Disadvantages: Poor weatherability, difficult to process, cost Common Uses: Food service, automotive, medical/healthcare, aerospace, engineering applications Brand Examples: HiFill, Thermocomp - POLYETHYLENE ETHER (PPE)

Strength: Med – High Strength at Elevated Temp: Med – High Resistance to Impact: Med – High Material Flow: High Resistance to Shrinkage/Warpage: Med – High Resistance to Flash: Med Cost of Resin: High Impact on Mold (wear): Med Advantages: Excellent electrical properties, resistant to acids and bases, can be blended with PS to improve processability and toughness Disadvantages: High viscosity, high cost, color degrades with UV Common Uses: Automotive, electrical and industrial applications Brand Examples: Ashlene, Norpex - POLYAMIDE (NYLON)

Strength: Med Strength at Elevated Temp: Low Resistance to Impact: High Material Flow: Good – Excellent Resistance to Shrinkage/Warpage: Fair Resistance to Flash: Poor Cost of Resin: Med Impact on Mold (wear): Low – Med Advantages: Food contact acceptable, easily processed Disadvantages: Degraded by UV Common Uses: Bearings, medium stress components Brand Examples: Akromid, Celanese, Zytel - POLYAMIDE (NYLON) – GLASS FILLED

Strength: High Strength at Elevated Temp: High Resistance to Impact: Med Material Flow: Good – Excellent Resistance to Shrinkage/Warpage: Poor Resistance to Flash: Fair Cost of Resin: Med Impact on Mold (wear): Fair Advantages: High Strength, wear and chemical resistance Disadvantages: Common Uses: Metal replacement, connectors, bushings Brand Examples: Capron, Zytel - POLYPHENYLENE SULFIDE (PPS)

Strength: High Strength at Elevated Temp: High Resistance to Impact: Low – Med Material Flow: Low – Med Resistance to Shrinkage/Warpage: Low – Med Resistance to Flash: High Cost of Resin: High Impact on Mold (wear): Med Advantages: Lubricated, electrically conductive, good wear Resistance, flame retardant, high strength Disadvantages: Difficult to process, fillers required for impact strength, high cost Common Uses: Automotive, medical/healthcare, engineering, and electrical applications, metal replacement Brand Examples: Celstran, Fortron - THERMOPLASTIC ELASTOMER (TPE)

Strength: Low Strength at Elevated Temp: Low Resistance to Impact: High Material Flow: Excellent Resistance to Shrinkage/Warpage: Poor Resistance to Flash: Poor Cost of Resin: Low – Med Impact on Mold (wear): Low Advantages: Good weatherability, recyclable, good UV Resistance, good adhesion, good colorability Disadvantages: Common Uses: Rubber replacement, bushings, seals Brand Examples: Elastocon, Santoprene - THERMOPLASTIC POLYURETHANE (TPE/TPU)

Strength: Med Strength at Elevated Temp: Low Med Resistance to Impact: Med Material Flow: Low Resistance to Shrinkage/Warpage: Med Resistance to Flash: Med Cost of Resin: Med Impact on Mold (wear): Low Advantages: Wide durometer range, oil, chemical and hydrolysis resistant, good wear resistance Disadvantages: Limited service temperature, processability Common Uses: Gaskets, surgical instruments, sporting goods Brand Examples: Celstran, Elastollan

- ACETAL (POM)